Advanced Oxidation Processes

Advanced Oxidation Processes (AOPs) are treatment technologies used alone or in combination, whose purpose is oxidizing/degrading residual organic matter in wastewater streams. While there are many secondary reactions and energy sources available to contribute to the oxidative capacity of every AOP process, for the most part the primary reaction source for each is the hydroxyl radical (•OH). Because every application requires a solution designed specifically for the matrix and project goals, we maintain partner relationships with manufacturers having expertise in all the main technologies: UV-H2O2, UV-O3, Plasma, etc.

Aeration

Whether surface and subsurface, aeration systems are intended to transfer oxygen from the gas phase (air above the water surface), into the wastewater either by creating interfacial surface area across which oxygen pass, or by directly injecting air bubbles into the water in an effort to increase the dissolved oxygen levels of the liquid. The purpose being to have a direct oxidative effect on contaminants, or more often to provide additional dissolved oxygen to a biological process that benefits from it. Aeration can have a very positive effect on many wastewater characteristics such as BOD levels, H2S levels, TOC levels and more.

Biogas

Biogas is produced after organic materials are broken down by bacteria in an oxygen-free environment, a process called anaerobic digestion. Biogas systems use anaerobic digestion to recycle these organic materials, turning them into biogas, which contains roughly 50-70 % CH4, 30-40 % CO2, and trace amounts of other gases. Anaerobic digestion occurs in nature, but also in most Food & Beverage treatment facilities. Mosaic has partners who are experts in biogas optimization, control, purification and storage.

BOD/COD Removal

While prominent in industrial wastewaters like those found in Food & Beverage, Biological and Chemical Oxygen Demand (BOD & COD) can be a challenge anytime there are significant carbon sources. Treatment approaches are many, and selection depends on the form and quantity of the carbon source, the gal/day of wastewater to be treated, and the limits to which it needs to be reduced. This is an area of technology development that has grown and diversified rapidly in the past 10-15 years, and we have access to technologies you are probably familiar with and others we are sure you are not.

Boiler Feedwater

Proper boiler feedwater treatment helps preserve steam quality, boiler efficiency and equipment uptime. Controlling alkalinity, scaling, pH and conductivity are critical to long trouble-free lifetimes for the boiler tubes.

Clarification & Sedimentation

Sedimentation is technically a process whereby suspended solids are gravity settled in a (still/quiet) tank, whereas Clarification is understood to involve passive or active settling OR flotation. At their simplest, both are solid-liquid separation steps. Historically suspended solids whose density was greater than that of water were settled, whereas less dense solids were often floated. Today that’s a very general rule, as solid-liquid separation technologies now exist that offer excellent performance regardless of serious density consideration. We place solids contact clarifiers, DAFs, Disk Filters and UFs into clarification applications depending on the host of considerations unique to each project. Let us know what you need to accomplish and we’ll get you pointed in the best direction for you and your specific application.

Cooling Tower Water

In order to ensure proper long-term performance of your cooling towers, water treatment approaches include filtration and softening in order to remove damaging impurities.

Desalination

Desalination systems have become an essential technology in the fulfilling of freshwater supply requirements globally. As waster scarcity and climate change make freshwater availability more and more challenging, desalination systems are helping the world meet demand requirements. Desal systems utilize high-pressure pumps to force saltwater through RO membranes which allow the transfer of water through sub-micron pores while prevent salt impurities from passing, resulting in clean/salt-free water for use as drinking water or in manufacturing applications requiring high-purity water sources. Historically Desal systems had been unrealistically expensive to build and maintain for most companies and communities, though recent advances in system design, pumps and especially membrane materials/construction have made their consideration quite feasible. Let us know about your project and we will introduce you to one of our several Desal partners.

Dewatering

Sometimes applications require a particular dewatering technology and sometimes our customers just ask for a specific type. Whether a plate press, belt filter press, screw press or other technology, we work with the best industrial dewatering companies in the world.

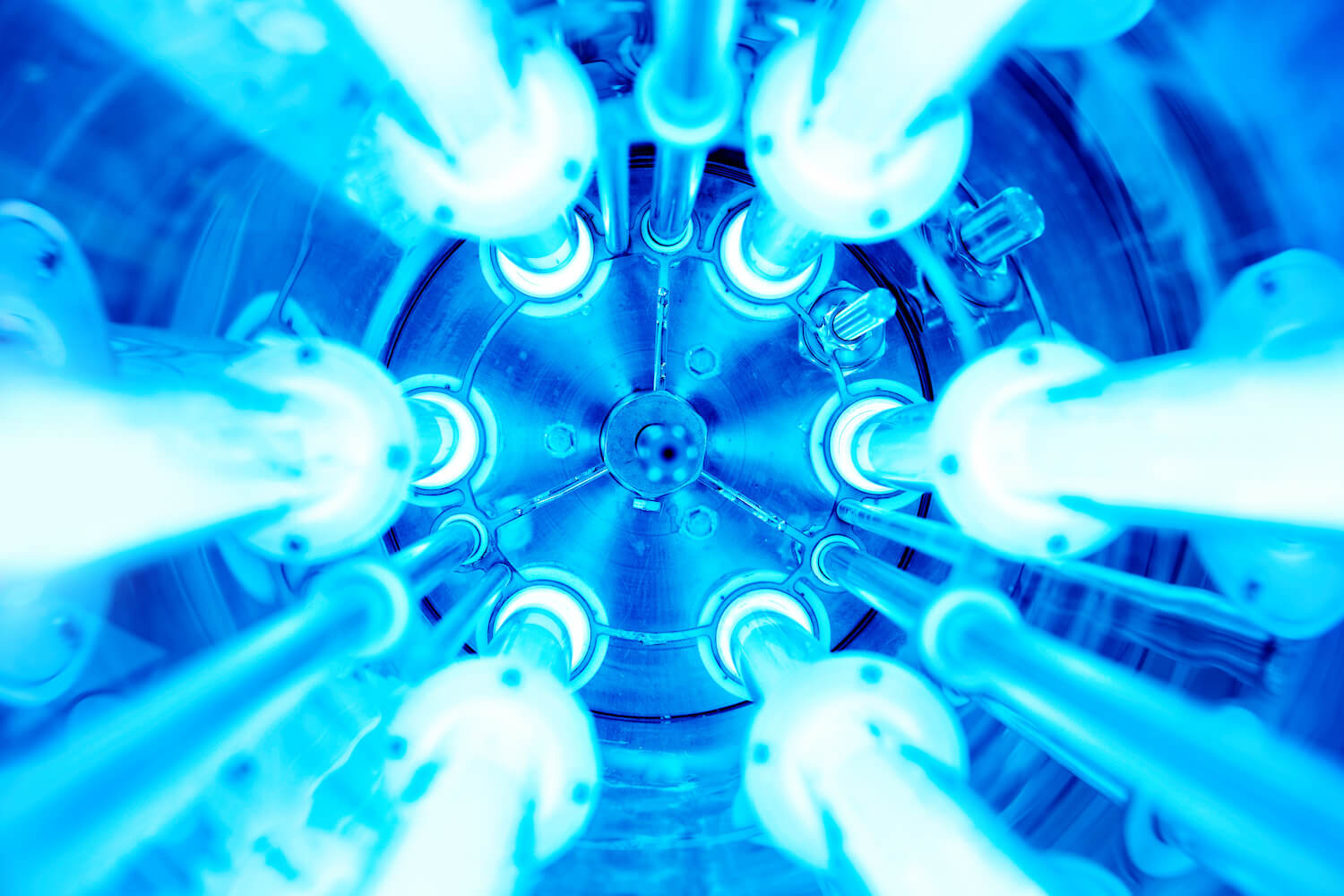

Disinfection

Disinfection can be accomplished by a number of chemical and non-chemical means including chlorination, ultraviolet treatment, peroxide treatment and ozonation to name the most common ones.

Granular Activated Sludge

The AquaNereda® Aerobic Granular Sludge Technology from Aqua Aerobic Systems is an innovative wastewater treatment technology that provides advanced biological treatment using the unique features of aerobic granular biomass. The unique process features of the AquaNereda technology translate into a flexible and compact process that offers energy efficiency and significantly lower chemical consumption.

Heavy Metals

Metals and semimetals can be removed in so many different ways that it is truly a “devil is in the details” topic. Depending on flow, constituents of interest, required removal rate, reuse opportunities and a myriad of other considerations, we’ll help you select an ideal path forward. Whether chemical precipitation, ion exchange, bioaccumulation or another treatment approach, we’ll make sure all your project goals are considered en route to a situationally best practice for metals removal.

High Density Sludge

The high-density sludge (HDS) process for acid mine drainage treatment has become a preferred method of treating mine water with high metal concentrations. The method is based on the addition of slaked lime to raise the pH and precipitate the metals as hydroxide sludge that settles to a much higher density than can be achieved by conventional alkali neutralization. The HDS is achieved as part of a two stage process: 1) lime neutralization, and 2) recirculated sludge acting as a seed for additional metals precipitation.

Hydrofluoric Acid Neutralization

Our partners have expertise in designing and manufacturing fluoride removal systems for the reduction of fluorine from wastewater sources including hydrofluoric acid, buffered oxide etches, ammonium bi-fluoride, fluorine scrubbers and more. While most systems for HF treatment tend to be small batch systems capable of handling a couple hundred GPD, we can also supply continuous-flow systems capable of handling 1 MGD or more.

Landfill Leachate

Landfill leachate is the liquid that leaches or drains from a landfill and are formed primarily when rain water filters through wastes placed in a landfill. While no two landfill leachates are identical, and individually can be composed of constituents specific to geographies or industrial neighbors, there are some themes that tend to be common for most. Landfill leachate is typically characterized by high chemical and biological oxygen demand and generally consists of undesirable substances such as organic and inorganic contaminants including heavy metals and ammonia. Treatment approaches include physical, chemical and biological methods including ultrafiltration (UF), lime precipitation and membrane bioreactors (MBR).

Microplastics

Microplastics come in a wide variety of sizes and chemical compositions, and include fibers, flakes, foams and pellets; Mosaic has a variety of sub-5 µm filtration technologies capable of removing 95%+ of particulate microplastics.

Nitrate/Ammonia Removal

With Total Nitrogen (TN) as a nutrient concern in water, being added to a majority of industrial discharge permits, Mosaic naturally has TN removal high on our radar. While we have several approaches for nitrification and denitrification, our partner WesTech has a particularly exciting technology for TN removal. An Electro-Biochemical Reactor (EBR) accomplishes high-efficiency denitrification, metals, and inorganics removal technology by providing electrons directly to the EBR bioreactor as a substitute for using excess electron donors and nutrients. Ask us about the WesTech EBR for your TN application.

Nutrients

Nitrogen and phosphorus from human waste and fertilizer runoff are the primary causes of eutrophication/algal blooms in surface and inland waters. Removal of TN and TP can take place via a number of treatment techniques depending on inleunt levent of each, wastewater flow and target effluent limits. As with most wastewater constituents, nutrient removal can be achieved through a number of biological, chemical and physical treatment techniques depending on the water characteristics and treatment requirements.

PFAS

It was reported recently that per- and poly-fluoroalkyl substances (PFAS) are believed to be in every surface water on the planet due to their integration into the earth’s water cycle, and their environmental persistence. Having been shown to pose health risks to human and wildlife, and surge in related regulatory requirements the removal of PFAS from waste and drinking waters, treatment efforts have skyrocketed in 2022 alone. It is currently known that three treatment processes can be effective for PFAS removal: granular activated carbon, ion exchange resins, and high-pressure membrane systems. Mosaic has a number of partners focused on technology development, and the first company to market with an accurate PFAS analyzer. Ask us about PFAS treatment and click below to lear about our solutions.

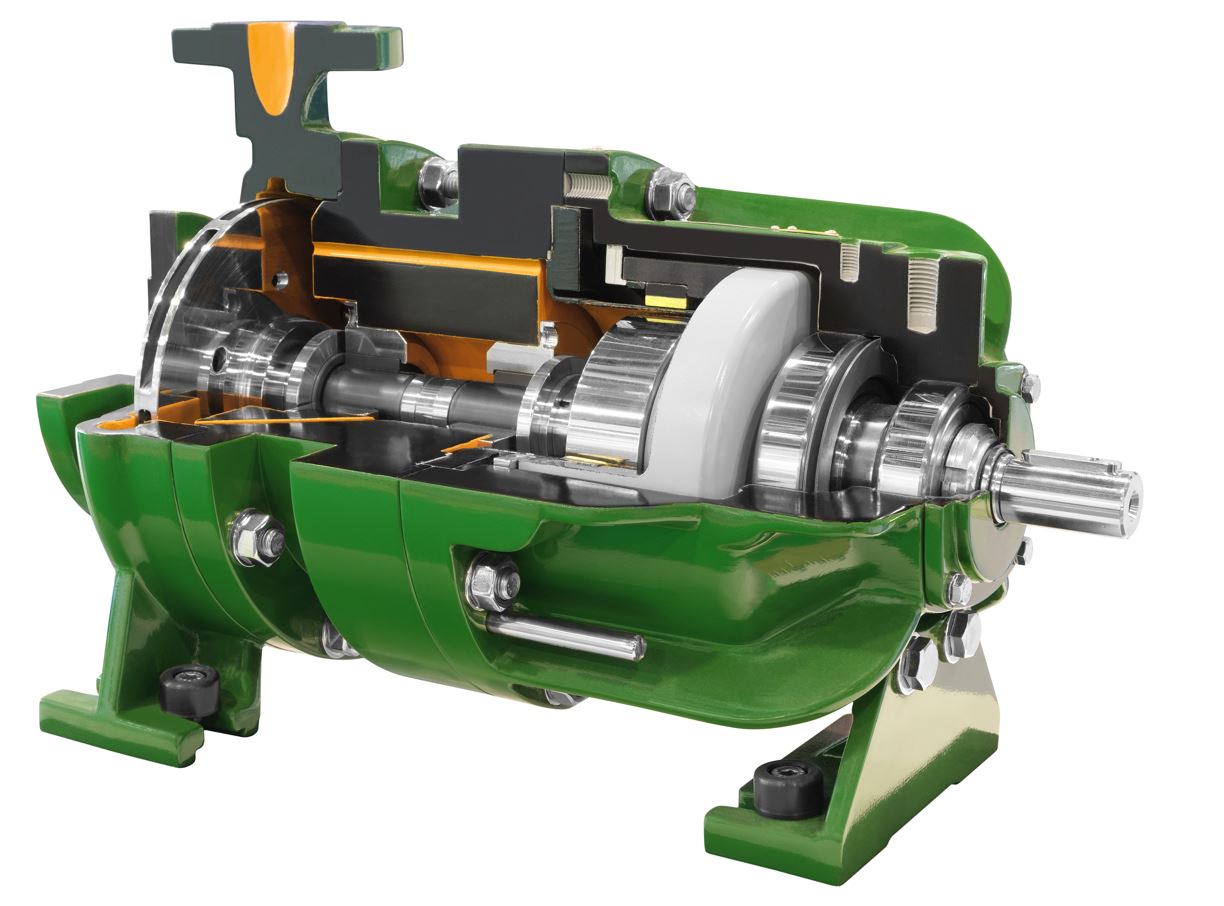

Pumps

We have pumps for almost every industrial application, from small-dose chem feed hose pumps to large volume vertical turbines. Call us for a quote and let us put our expertise to work for you.

- Chemical Feed

- Grinder

- High Pressure

- Peristaltic Hose

- Precision Metering

- Submersible

- Vertical Turbine

Radionuclides

As is the case with most water/wastewater contaminants, the applicability of different equipment and techniques for removing radionuclides (Gross Alpha, Ra, Rn, U, etc.) depends on flow, budget, location, influent levels/effluent requirements, and other considerations.

For larger flows Mosaic can provide individual unit processes that seamlessly plug into existing treatment plants, as well as packaged systems for smaller flows that are completely turnkey. Frequently used treatment approaches include:

- Granular Activated Carbon (GAC)

- Greensand

- Ion Exchange

- Reverse Osmosis

Recycle/Reuse

Decades of bad water management policies combined with manmade climate change stress have driven water supplies in the western US so low that more and more states are being forced to institute strict (radical?) water management policy. Whether driven by regulations or by enlightened corporate sustainability policies, the recycling and reusing of industrial wastewaters has become part of more than 70% of Mosaic treatment plant projects. Wastewaters can be treated to any level of cleanliness necessary, from irrigation-quality to ultra-pure, and Mosaic can provide support regardless of your starting water quality or final quality goals.

Reuse/recycle technologies:

- Evaporation/Distillation – some wastewaters are very challenging to treat and are sent to evaporators instead of a traditional chem/phys means of treatment. Even these waters can be sent to evaporators with distillation systems that can reclaim deionized water quality product.

- Media Filters – several filter types are available for tertiary filtration of treated wastewater, each capable of producing irrigation-quality waters as a result:

- Cloth Disk Filters

- Multimedia Filters

- Sand Filters

- Membrane Treatment (MBR/MBBR/MF, UF, NF, RO)

- MBR/MBBR – High BOD/COD waters can be treated biologically with membrane systems resulting in reuse-quality water.

- Compared to Microfiltration (MF), Ultrafiltration (UF), Nanofiltration (NF), and Reverse Osmosis (RO) are all higher-pressure membrane separation processes that can provide very high-quality reuse waters (even potable).

Selenium

Selenium is a naturally occurring mineral found in pyrites of copper and iron, sulfide ores of copper, lead, nickel, gold and silver. It is encountered in these compounds at levels ranging from 0.02-2 ppm, but drilling/boring activities common to mining and oil & gas industries both liberate and concentrate selenium. While Se is actually required by the human body in micro amounts, larger doses or prolonged exposures can lead to serious negative health effects in animals including humans. Selenium is found generally in four different oxidation states: selenide (2-), elemental selenium (0), selenite (4+), and selenate (6+), with the latter two being more common. Selenate has the highest solubility in water making it more challenging to remove. Selenite is soluble in water as well, but unlike Selenate, its adsorption affinity is high, making it a candidate for removal by a variety of adsorptive media. The most common approaches to Se removal include biological treatment and membrane separation.

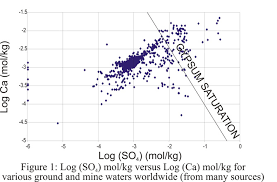

Sulfate Removal

Sulfate concentrations in wastewaters have come under increasing scrutiny from regulatory authorities recently. In contrast to other contaminants of growing concern such as nutrients and heavy metals, sulfate has no primary drinking water standard. While many treatment technologies have been developed to remove sulfate from wastewaters, heavily impacted waters are typically faced with the production of large amounts of gypsum (calcium sulfate) after lime precipitation. Mosaic has novel treatment approaches for the removal of both higher and lower SO4 concentrations.

TSS Polishing

“Suspended solids” refers to suspended matter that is suspended either on or within wastewater, and which is removable by flotation, settling or filtration. Some of the most common chem/phys technologies that are deployed in this application include:

- Dissolved Air Flotation (DAF)

- Suspended Air Flotation (SAF)

- Ultrafiltration (UF)

- Cloth Disk Filters

- Sand/Media Filters

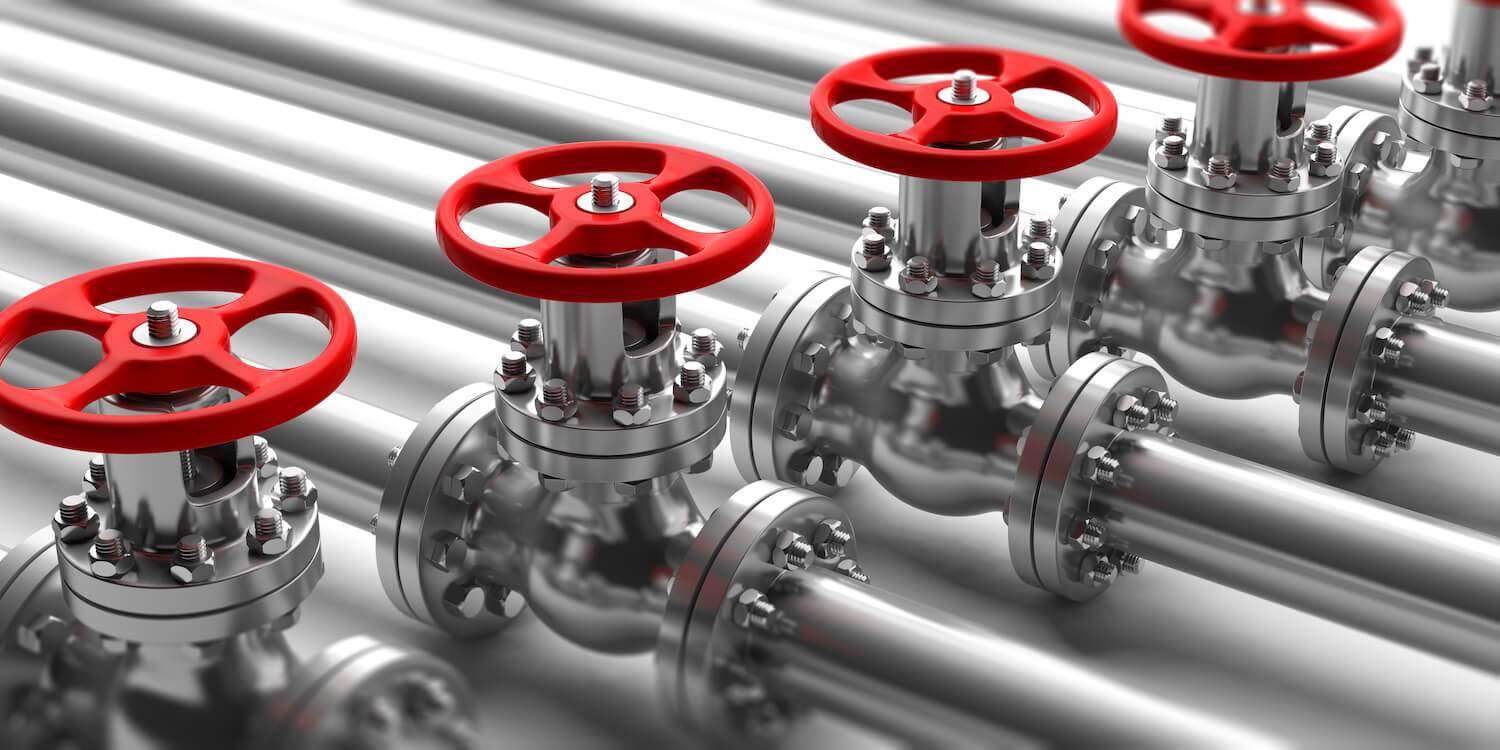

Valves

Mosaic is proud to be partnered with Bray Valves. Bray is the industrial leader in Ball, Balancing, Butterfly, Check, Globe valves and Actuators. With over 30 years of continued success and global operations in over 40 countries, Bray is one of the premier manufacturers of flow control and automation products and accessories in the world. Their modular product line of valves, actuators and accessories offer the best compatibility, economy and quality performance in the flow control industry. Bray is the valve of choice in the most challenging industrial applications.

Zero Liquid Discharge (ZLD)

Zero Liquid Discharge (ZLD) is a wastewater treatment design approach that seeks to recover all the water possible for reuse/recycle, while contaminants are reduced to solid waste. Because the cost and challenge of clean water recovery increases with each successive re-treatment step, it is often the case with ZLD projects that a practical limit is reached where 90%+ recycle becomes acceptable for most projects. In fact, the term that has been adopted to better communicate this understanding is “near-ZLD.” The most common treatment technologies utilized in ZLD projects are:

- Distillation

- Evaporation

- Ultrafiltration (UF) and Reverse

- Osmosis (RO)

Contact Us

Curtis Wood

(720) 546-5892

curtis@mosaicwatersystems.com

Will McHale

(303) 656-5498

will@mosaicwatersystems.com